Automated Image Analysis

Predictive Modeling

Process Automation

Process Information Rapid Assessment Toolkit (PIRAT)

Iterative evaluation based upon process statistics and knowledge

- Evaluate original design for AM state

- Predict overall performance and strength (3D)

- Identify layer by layer metrics (2D)

- Assess image data (pre- and post-layer, Tomography, etc.)

- Identify and classify anomalies and defects

- Update layer metrics based on known defect resolutions

- Inform user to anomaly/defect level

- Predict/score part health status

- Identify actions for next layer (continue, adjust, stop)

- Inform users with status and recommended actions

- Automate process actions

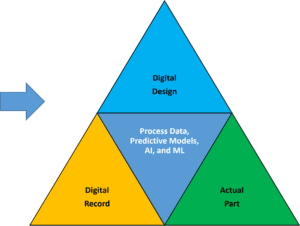

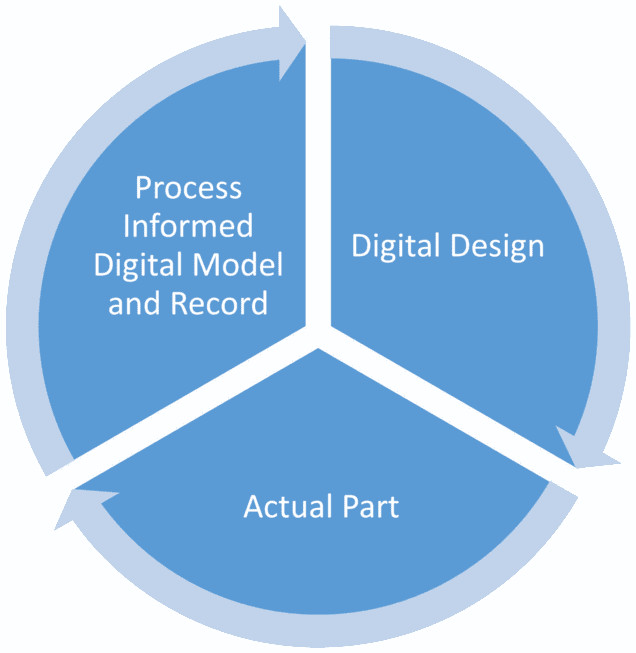

Plan for Digital Engineering for AM

- Design: for Additive Manufacturing (Digital Design – Actual Part)

- Print: Test specimens and parts

- Collect: in-process measurement of process results (Digital Record – Digital Design – Actual Part)

- Test: Alloy Information, Validation, and Performance,

- SAVE: Digital Records

Digital Models and Documentation

Digital Records

- Alloy properties

- Digital Designs

- Process recipes and parameters

- In-process sensor data and Image analytics

- Relevant post-process test documentation and data

- Predictive models

- Process metrics

- ML Algorithms

- Information flow

- Automation flow

- Reports

CDME AM Lab

CDME has extensive capabilities in metal, ceramic, and polymer printing technologies including laser powder bed fusion, electron beam powder bed fusion, directed energy deposition, binder jetting, stereolithography, and FDM

Laser Fusion Solutions (LFS) Facilities and Equipment

- LFS has its research headquarters in the Dayton Ohio area and an additional manufacturing facility partner in the Huntsville Alabama area.

- LFS owns two EOS M280s, an EOS M270, and a Concept Laser XLine 1000R for full scale production.

- Systems can have numerous sensor packages added to them to be readily adopted for quality control on current manufacturing builds.