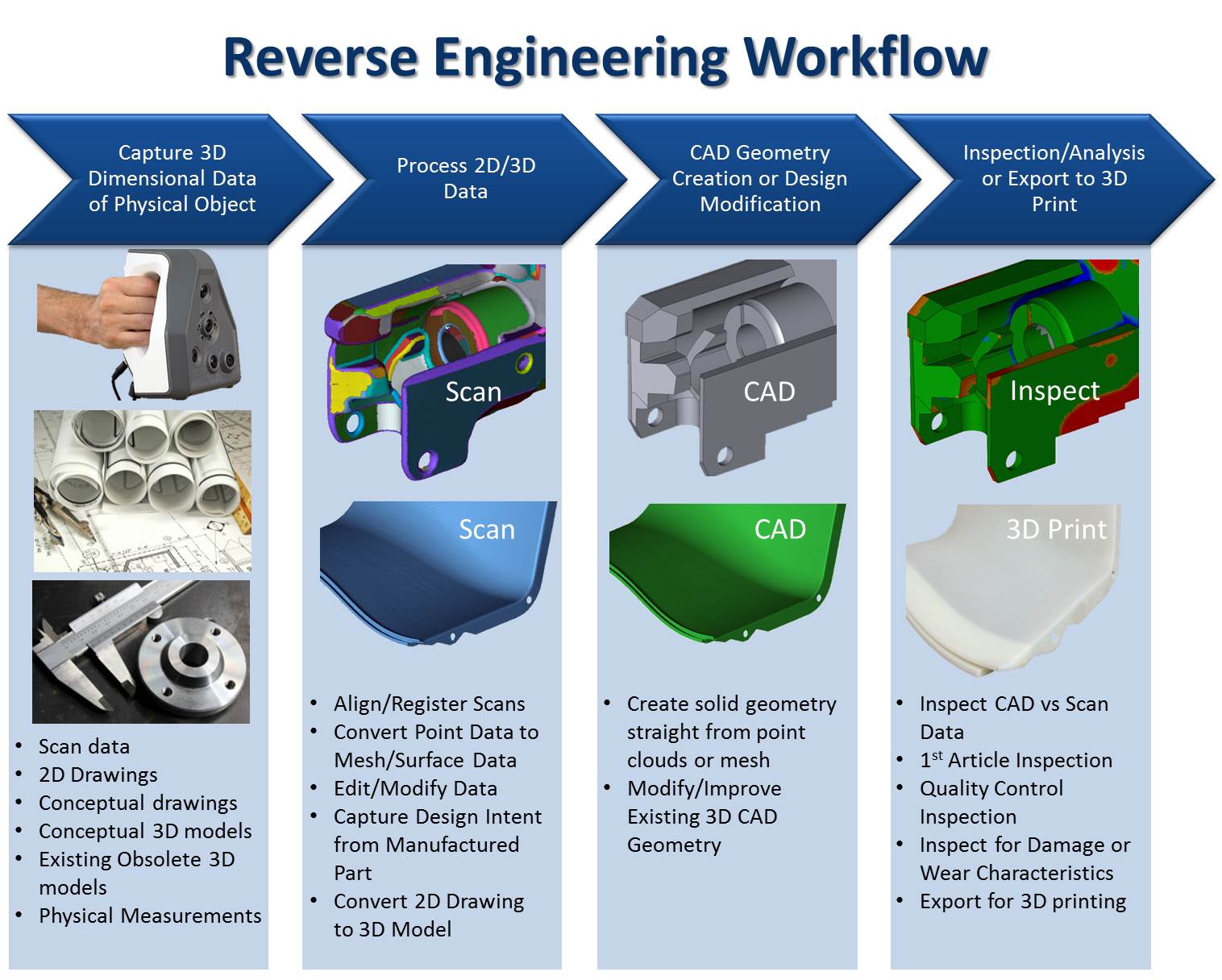

Skyward can create 3D models of scanned objects or manipulate 3D models provided by customers to accomplish a variety of jobs. Triangulated scan data can be exported into the format of your choice (i.e., STL, Obj, Ply, VRML, Ascii, PTX and others) or converted directly to CAD for geometry creation, design modification, and/or manufacturing. 3D models can even be exported into file formats compatible with most additive manufacturing 3D printers. 2D engineering drawings can also be created from scan data or 3D models, when necessary, for production. Skyward can assist in reverse engineering projects, using scanning technologies to define an object in 3D space and then create a model and drawings which did not exist before. In many industries, 2D blueprint drawings may be all that exists to describe a part. Scanning and 3D modeling can create an electronic means to archive the information more efficiently and with greater longevity.

Parametric 3D Modeling:

- Create models from hand drawn sketches, photographs, or digital media (e.g., 3D scan data)

- Modify existing models from old or outdated software (can import from a variety of existing and past data formats)

- Create models with feature trees and make modifications within the history tree

- Develop models of a single customized component for mass production (e.g., health care, dentistry, fashion, hobbyists, etc.)

- Produce outputs in multiple industry standards (i.e., IGES, STEP, STL, Parasolid, etc.) using CAD tools such as SolidWorks and Geomagic Design X

- Geomagic Design X can live transfer CAD models and features natively into SolidWorks, Creo, Siemens NX, AutoCAD, or Solid Edge)

Design Modification

- Evaluate design integration (form, fit, and function)

- Update existing component models or create new models based upon current designs (form and fit)

Reverse Engineering:

- Create 3D CAD models of lost or obsolete designs

- Convert scans to CAD models

- Create 2D Interface Control Drawings (ICDs)

- Create geometric descriptions for modeling

- Compare scanned components against manufactured parts to determine dimensional tolerance compliance

Ongoing Commercial Projects

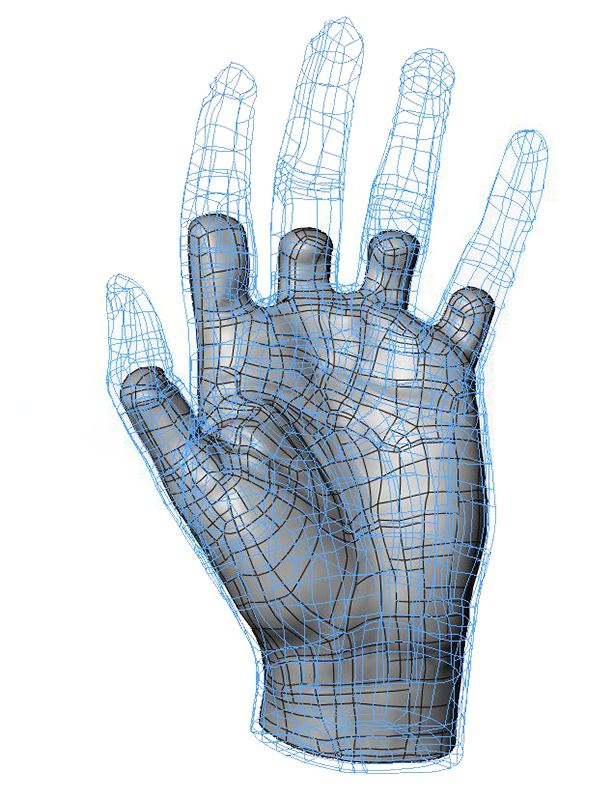

Our talented 3D team has worked on numerous commercial projects that highlight not only the advanced tools at our disposal, but our ability to scan objects with complicated, organic shapes. We have supported customers involved in the arts, restaurant operation, automotive design and restoration, aerospace applications, firearms development, and machining applications.

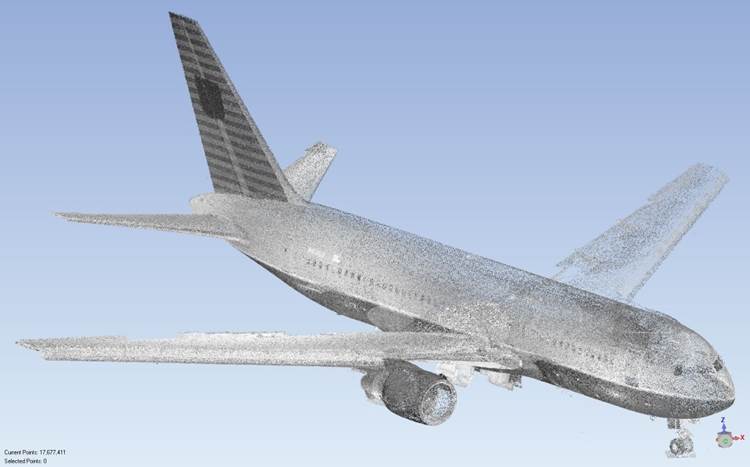

Skyward utilizes a variety of state-of-the-art 3D scan technologies (i.e. short/long range, portable handheld, blue light, white light, laser, etc.) and in-house expertise to acquire high resolution/high fidelity scan data of a wide range of physical objects, varying in both size and complexity. Skyward is an approved Artec 3D service provider (Artec 3D scanning provider map), primarily providing service in Dayton, OH and surrounding areas.

Examples of 3D scanning technologies employed by Skyward include:

- Large Scale: Surphaser (100HSX model) – buildings, aircraft, ships, etc.

- Medium Scale: Artec 3D Eva; Artec Spider – people, automobiles, large mechanical components, etc.

- Small Scale/High Precision: Breuckmann SmartScan/StereoSCAN – small electronic and mechanical components, jewelry, etc.

Full Dimensional Component Inspection:

- Compare scanned components against manufactured parts to determine dimensional tolerances

- Develop full dimensional color maps showing areas of non-compliance with tolerance specifications

- Compare pre/post-event scans of components (e.g., tests, wear from usage, etc.) to determine differences

Applications/Industries of 3D scanning include:

- Prototype or non-destructive parts inspection

- 1st article inspection

- Reverse engineering of obsolete parts

- Aging aircraft, automotive historical restoration, etc.

- Die/Mold inspection

- Military/Commercial Automotive, Aerospace, Naval/Marine

- Telecommunications/Satellites/Space

- Energy (Oil/Gas, DoE, Wind, etc.)

- Medical/Dental

- Consumer Products/Household Applications

- Engineering Design and Materials Analysis

- Archeology

- Gaming, animation, videography/cinematography, rendering, etc

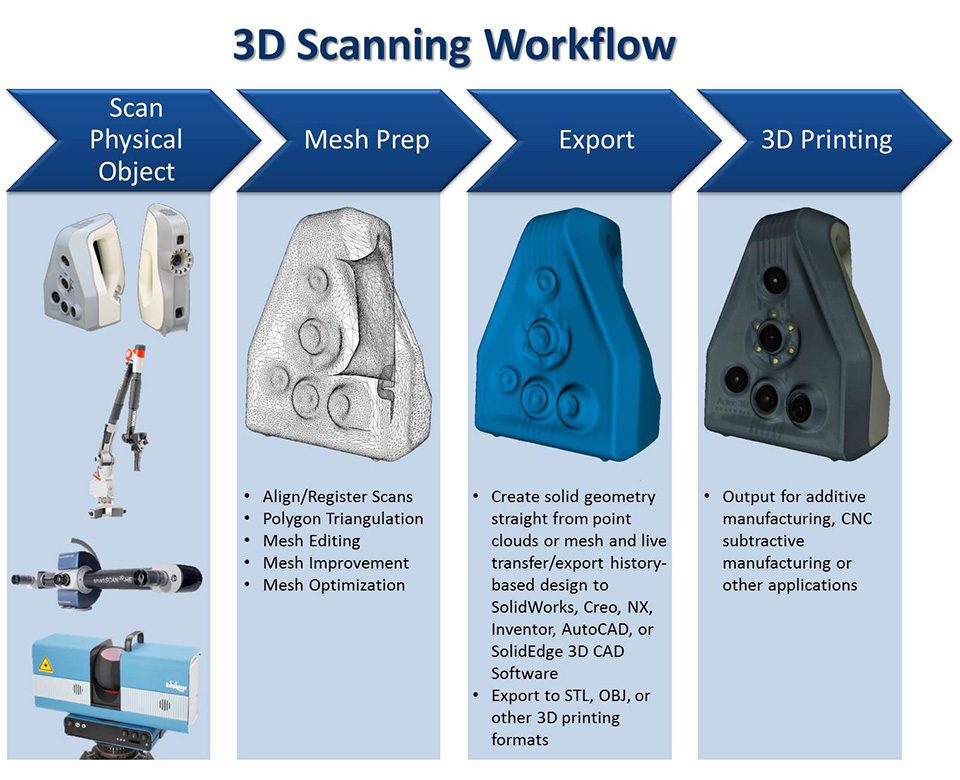

3D Scanning Workflow:

Multiple scans are captured of an object or surface with extra emphasis on complex or complicated areas. The scans are aligned and registered to create a single 3D point cloud. Fusing scans together produces a triangulated mesh, which can be edited and optimized for a variety of post-process applications, including full dimensional inspection and CAD geometry creation. Finished scans can then be exported for rapid prototype 3D printing using emerging additive manufacturing technologies.